electroplating using titanium anode baskets

Titanium wire anode basket general introduction:

Grade 2 titanium is used most widely in the commercially pure titanium.

The density of titanium is 4.506-4.516g/cm3, melting point is 1668 degree, boiling point is 3535 degree. In the appropriate oxidizing environment, titanium also has excellent corrosion resistance. Therefore, titanium products are widely used in aerospace structural materials, such as aircraft, rockets, missiles and spacecraft, ship manufacture, chemical industry, conventional weapons, manufacturing, metallurgical industry, health care, ultra-high vacuum and other fields.

Titanium wire anode basket general introduction:

Grade 2 titanium is used most widely in the commercially pure titanium.

The density of titanium is 4.506-4.516g/cm3, melting point is 1668 degree, boiling point is 3535 degree. In the appropriate oxidizing environment, titanium also has excellent corrosion resistance. Therefore, titanium products are widely used in aerospace structural materials, such as aircraft, rockets, missiles and spacecraft, ship manufacture, chemical industry, conventional weapons, manufacturing, metallurgical industry, health care, ultra-high vacuum and other fields.

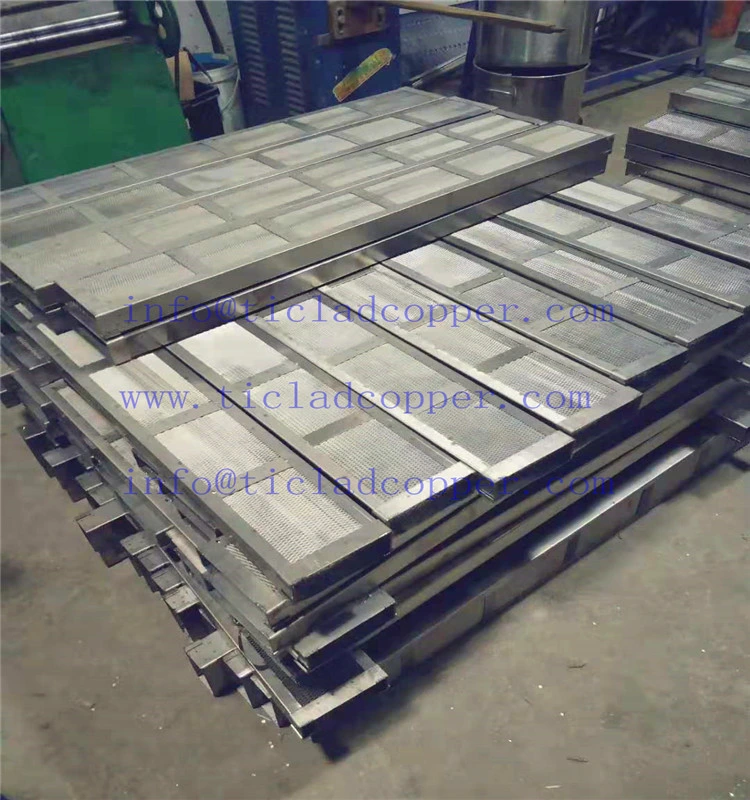

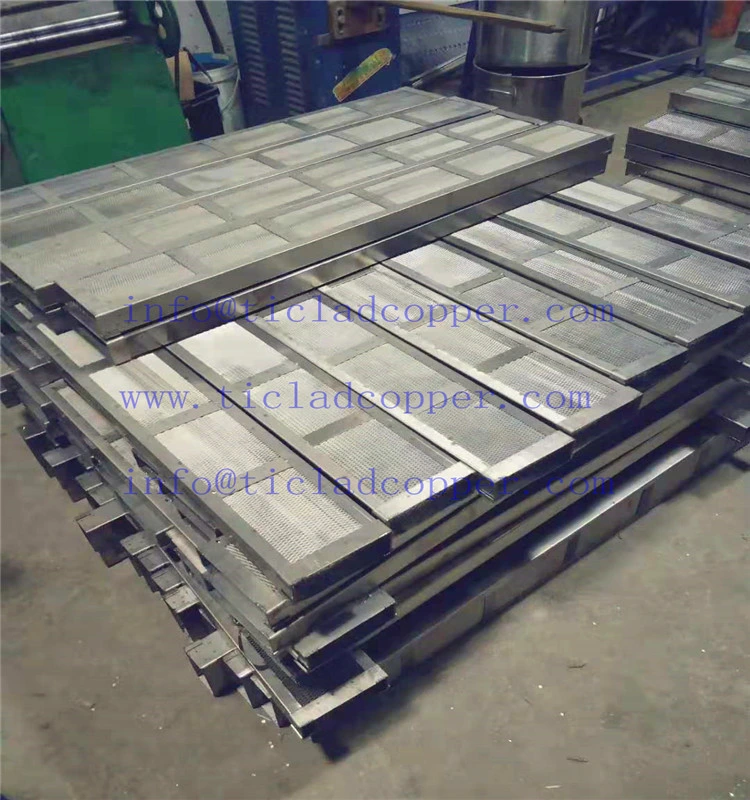

| Item name | Titanium anode basket |

| Material | Pure Gr1 or Gr2 titanium |

| Dimension | Length x Width x Thickness 400x120x50mm,500x130x55mm,600x150x55mm, 700x175x60mm, 800x195x60mm,900x215x65mm, 1000x250x65mm,400x120x50mm,500x130x55mm, 600x150x55mm,700x175x60mm,800x195x60mm, 900x215x65mm,1000x250x65mm, 750*40*35mm 200*630*40mm, 250*1150*60mm, 250*700*50 mm, 760*40*105mm, Or according to customer's design |

| Mesh Hole Size | 6*3 mm, 5*4 mm, 8*4mm, 10*5mm, 12.5*4.5mm |

| Hole shape | rhombus or round |

| Manufacturing method | Cut, Bent, Welded |

| Applications | Electroplating industry :

3)Base metal plating (Cu, Zn, Ni) 4)Precious metal recovery |

| Kindly noted | 1,Titanium basket mouth should be slightly higher level 30-40mm, in order to prevent the outflow of anode residue 2,Titanium basket end parts should be higher than 100 ~ 150mm (near surface side may consider installing shutters), in order to avoid the lower parts of the current is too concentrated, causing burning 3, Titanium basket should be in close contact with the anode, the anode potential otherwise titanium basket on the sharp rise in the surface of the titanium basket and chlorine evolution occurs oxygen evolution reaction, cause oxidative damage and additives titanium basket |