extruder soya/extruder taiwan snack food/soya extruder machine

Description:

consisting of two co-penetrating and self-cleaning identical screws which are mounted on shafts and rotate in the same direction in a fixed closed housing called "barrel" .The twin-screw extruders operate continuously with very short residence times. The High Tech of Keysong's Extruder are:

1.Applied to various materials with totally enclosed type compulsive feeding way.

2.Cordwood combined screw is applied to different materials and products with certain screw combination.

3.Flexible Application: Suitable for kinds of raw material, like cereal powder, grains:

4. With water injecting device on barrel, it can adapt to the requirements of materials and quality.

5.Die & Mould: Wide range of the shapes and size, easily use, and simply maintenance;

consisting of two co-penetrating and self-cleaning identical screws which are mounted on shafts and rotate in the same direction in a fixed closed housing called "barrel" .The twin-screw extruders operate continuously with very short residence times. The High Tech of Keysong's Extruder are:

1.Applied to various materials with totally enclosed type compulsive feeding way.

2.Cordwood combined screw is applied to different materials and products with certain screw combination.

3.Flexible Application: Suitable for kinds of raw material, like cereal powder, grains:

4. With water injecting device on barrel, it can adapt to the requirements of materials and quality.

5.Die & Mould: Wide range of the shapes and size, easily use, and simply maintenance;

Machine Parameters:

| Model | Installed Power | Power Consumption | Capacity/Output | Dimension |

| KS65-II Twin Screw Extruder | 42.9kw | 30kw | 100-180kg/h | 3070x960x2050mm |

| KS65-III Twin Screw Extruder | 31.3kw | 22kw | 100-150kg/h | 2600x960x2000mm |

| KS70-III Twin Screw Extruder | 64.45kw | 40kw | 200-250kg/h | 3320x960x2100mm |

| KS75-III Twin Screw Extruder | 79.05kw | 50kw | 250-350kg/h | 4650x1100x2200mm |

| KS85-III Twin Screw Extruder | 97kw | 72kw | 350-500kg/h | 4800x1100x2300mm |

| KS52-II Twin Screw Extruder | 54.3kw | 40kw | 100-150kg/h | 4500x900x1820mm |

| KS75-II Twin Screw Extruder | 89.7kw | 67.3kw | 200-350kg/h | 5200x1100x2200mm |

| KS90-I Twin Screw Extruder | 161.3kw | 121kw | 350-800kg/h | 5800x1200x2500mm |

Machine features:

1.Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

2.Flexible Formula: Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc;

3.Widly Appication: Easy adaptation to extend the range of products by changing the segments screw;

4.Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

5.Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters.

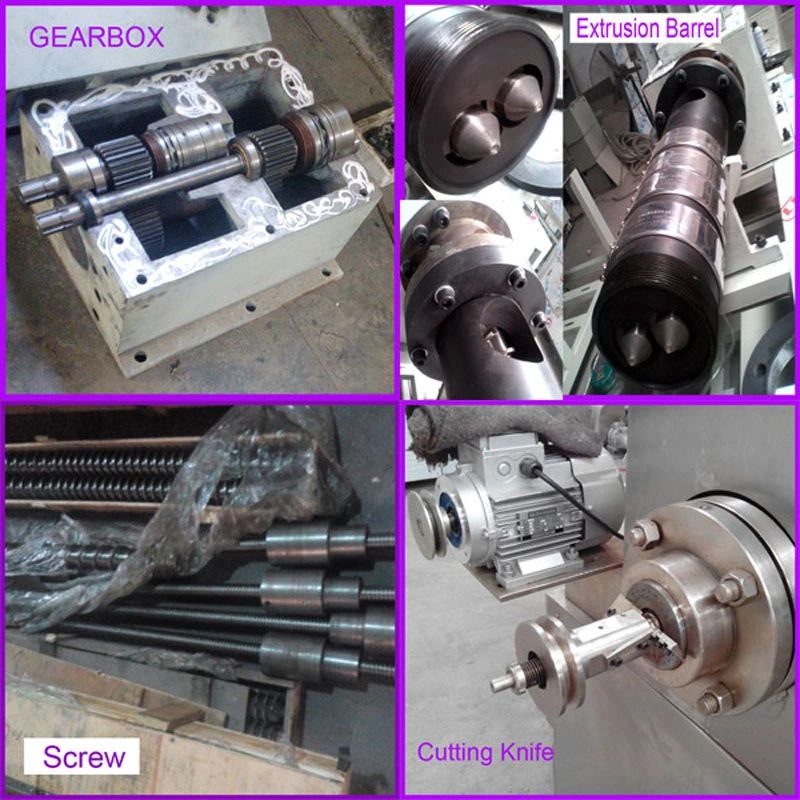

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.1.Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

2.Flexible Formula: Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc;

3.Widly Appication: Easy adaptation to extend the range of products by changing the segments screw;

4.Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

5.Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

Package and shipping:

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finally pack them with wooden case.

2).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

Our Service:

1.Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

2.During Production: Timely updates the machine status for customer to ensure delivery time, and quality;

3.After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

4.Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the custoemrs;

5.Installation & Training: Sending professional and expert technical engineers to providing employee training and installation service.

6.After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, spare parts etc;